In the wake of the global economic crisis, dwindling natural resources and ever-increasing needs of a growing population we face a stark question: how do we achieve global growth which does not cost the earth?

Peder Holk Nielsen, President and CEO of Novozymes A/S, believes the answer to this lies partly with industry, which must turn these challenges into a unique opportunity to build a biobased economy founded on a sustainable, low-carbon approach to energy and production. He believes that Novozymes’ innovative technology can help steer China on the path towards sustainable growth.

Peder Holk Nielsen, President and CEO of Novozymes A/S, believes the answer to this lies partly with industry, which must turn these challenges into a unique opportunity to build a biobased economy founded on a sustainable, low-carbon approach to energy and production. He believes that Novozymes’ innovative technology can help steer China on the path towards sustainable growth.

Biotechnology is already making the transition to a more ecologically sustainable economy possible by greening value chains in diverse industries such as textiles, paper and detergents. Biobased products are boosting agricultural yields, helping develop plastics based on renewable biomass rather than oil, and making biofuels from industrial and domestic waste a commercially viable alternative to gasoline.

The benefits include lower energy and resource costs for businesses, higher living standards for millions of consumers, clean industrial production, and a green infrastructure that fosters innovation, jobs and global growth. However, realising the full potential of the biobased economy demands sustained investment in innovation which is scalable and meets market needs.

Innovating for the market

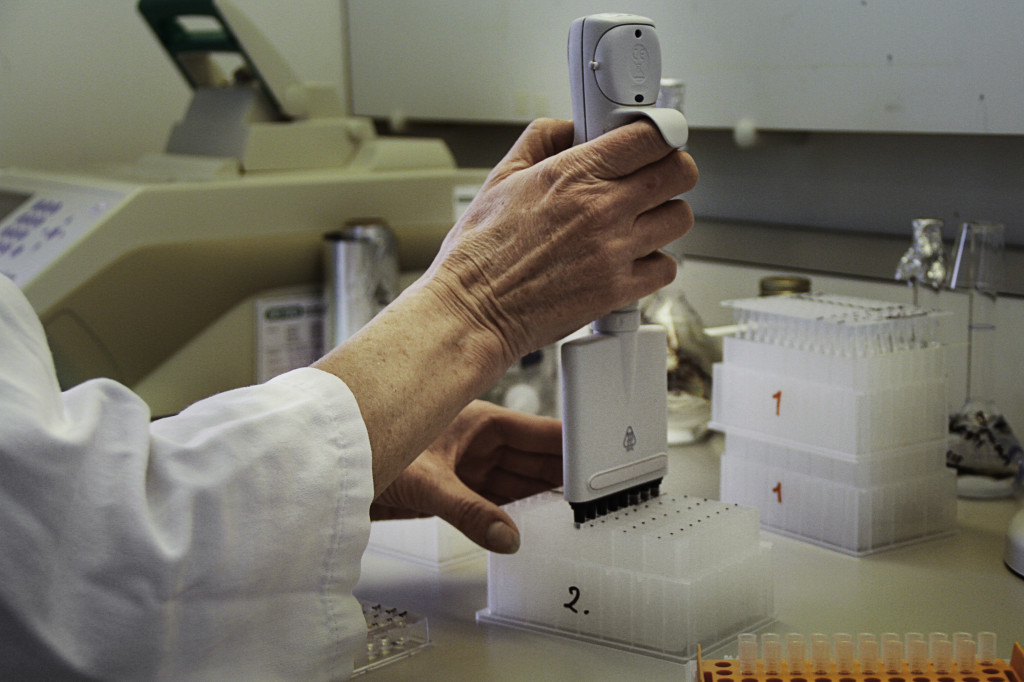

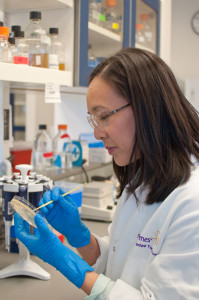

Innovation is the cornerstone of the biobased economy, and lies at the heart of Novozymes, the world’s biggest producer of industrial enzymes. Research and development (R&D) absorbs more than 20 per cent of the company’s global workforce and 13-14 per cent of its revenues. A unique industrial biotechnology platform helps it undertake innovation in step with market needs, and in close collaboration with customers. Their ultimate goal is to help their customers make more with less: more and better-quality products using less energy and fewer raw materials.

Innovation is the cornerstone of the biobased economy, and lies at the heart of Novozymes, the world’s biggest producer of industrial enzymes. Research and development (R&D) absorbs more than 20 per cent of the company’s global workforce and 13-14 per cent of its revenues. A unique industrial biotechnology platform helps it undertake innovation in step with market needs, and in close collaboration with customers. Their ultimate goal is to help their customers make more with less: more and better-quality products using less energy and fewer raw materials.

In order to gain a better understanding of which solutions in the company’s R&D pipeline could reduce environmental impact in the industrial area in which it is deployed, Novozymes employ life cycle assessments—a cradle-to-grave measure of a product’s environmental footprint. These considerations inform the process which determines whether a particular product is market viable. Typically, Novozymes introduce six to eight new products to market per year, and they hold some 7,000 granted or pending patents. These innovations serve a market need: helping their customers improve manufacturing processes and save resources and costs, which in turn improves overall sustainability.

China blueprint

China is a strong growth engine in Novozyme’s globalisation strategy representing their second largest market. The first China office was opened in Hong Kong in 1992 and moved to Beijing in 1997. It is one of the largest Danish investments in China with a total realised investment of more than USD 500 million by 2012.

Novozymes’ R&D Centre in Zhongguancun Science Park in Beijing employs around 200 scientists and researchers. It is the first foreign-invested biotech research institution in China, and the company is expecting to increase the staff and general operations in China.

Nielsen says that at Novozymes they closely observe the changes in the Chinese economy and hopes the business will grow faster than 10 per cent in China. The areas he has identified as having the most potential are in food, household care and bioenergy.

“We will have more and more people in China,” says Nielsen, “Today every fifth employee of Novozymes is a Chinese and I expect that over a period of five years there will be more people in China, relatively speaking, working for Novozymes: so more customers, more sales and more people in the company.”

Doing laundry, doing good

Doing laundry, doing good

Take, for example, the detergent industry, where enzymes have revolutionised how we do laundry. Enzymes are proteins that help speed up biochemical reactions in all living organisms. As they have one, unique function, and degrade into harmless compounds, enzymes are ideal tools for use in clean industrial production. Enzymes such as protease, lipase and amylase improve stain removal even when clothes are washed at 30 degrees Celsius, down from typical wash temperatures of 60 degrees, thereby cutting energy and chemical use, as well as reducing carbon dioxide (CO2) emissions.

As water is a critical sustainable development issue, Nielsen believes that Novozymes’ innovative biotech solutions could contribute to water saving in China. It has entered strategic partnerships with large detergent companies in China, Liby and Nice:

“Water is taking up a larger and larger piece of the agenda. In particular in China, there is a large textile industry. We have a lot of offerings for the textile industry which essentially reduces the requirements for rinses, so you don’t have to rinse as much and that’s where most of the water is spent,” he says.

Similarly, enzymes can replace chemicals in many stages of the textile manufacturing process. The enzyme pectate lyase, for instance, degrades pectin and removes wax from raw cotton, thereby enabling the textile scouring process to take place at lower temperatures and reducing the number of rinsing baths needed. By adopting enzymatic solutions, manufacturers could save 70−90,000 litres of water and around one ton of CO2 emissions per ton of knitwear. Were these solutions applied in the textile industry globally there would be potential savings of 630 billion litres water and nine million tons of CO2 annually.

Investing in tomorrow

Greener detergents and textiles may seem unlikely flagships for innovation in a world of smartphones, aerial drones and robotic limbs, but they are proof of technology that works, helps business earn bigger profits, delivers savings to consumers, and mitigates climate change. In 2012 alone Novozymes helped customers reduce their CO2 emissions by an estimated 48 million tons—corresponding to CO2 emissions from 12 large, coal-fired power plants—by the application of its various biosolutions across diverse industries. It is their ambition to significantly contribute to the goal a 75 million ton reduction in CO2 emissions in 2015.

Although many biotechnological solutions needed to support the greening of value chains in key, global industries already exist, more investment in innovation and research is needed to hasten and scale-up the transition to a biobased economy. More innovation is also needed to continuously optimise the biosolutions demanded by industry. Biotechnology and the biobased economy offer a realistic path to stimulate economic recovery in the post-crisis world and foster sustainable growth. Industries and governments must seize the opportunity to support this transition.

Novozymes is a biotech company with a strong focus on enzyme production; they have a global market share of 47 per cent (2011). They are committed to changing the very foundations of our industrial system for the better by using industrial biotechnology. They have more than 5,800 employees working in research, production, and sales around the world and are committed to shaping the businesses of today and the world of tomorrow.

Recent Comments