Navigating the impact of warmer weather on cold chain warehouses

Warmer weather is not just about a few degrees on the thermostat; it represents a fundamental change that impacts operational efficiency, energy consumption and product integrity. Nathalie Ieong and Thanh Tran of TERAO explore the multifaceted implications of rising temperatures on cold chain warehouses, with a particular focus on how strategic building design and construction are paramount in securing this indispensable link to the global supply chain.

The hum of refrigeration units is the heartbeat of a cold chain warehouse, diligently preserving everything from life-saving pharmaceuticals to fresh produce and delicate floral goods. However, as global temperatures continue to rise due to climate change, this important sector faces an unprecedented challenge – one that threatens not only product integrity and regulatory compliance but also profitability and sustainability targets. This warming trend is particularly evident in tropical regions such as Southeast Asia, and increasingly so across China.

The seemingly subtle increase in ambient temperatures has a cascading effect throughout cold chain operations, imposing significant stress on infrastructure and processes.

Perhaps the most immediate and obvious impact of warmer weather is a spike in energy consumption. Refrigeration systems, designed to maintain precise low temperatures, must work significantly harder to counteract higher external heat loads penetrating a building’s thermal envelope, meaning that they consume more electricity and cause electricity bills to soar.

This surge in consumption also directly contributes to increased carbon emissions, posing a significant challenge to corporate sustainability goals and Scope 2 reporting requirements. Studies have shown that energy consumption in cold stores can increase by up to 30 per cent, depending on operating conditions,[1] with cooling systems alone accounting for a substantial portion (around 44.1 per cent) of a factory’s total electrical energy consumption.[2]

This added burden not only inflates operating costs but also accelerates wear and tear on important equipment, demanding more frequent maintenance and raising the risk of costly downtime.

Compromised product integrity and increased spoilage

The primary purpose of a cold chain is to maintain the quality and safety of temperature-sensitive products. Even minor temperature fluctuations can have devastating consequences. For perishable foods, just a few degrees above the ideal range can accelerate spoilage, lead to bacterial growth, reduce shelf life by days or even weeks, and render products unsafe to consume.

In the pharmaceutical sector, temperature changes can reduce the effectiveness of vaccines and medications, posing serious public health risks. The United Nations Food and Agriculture Organization estimates that approximately 14 per cent of food spoils before it ever reaches retailers, causing losses of up to United States dollar 400 billion annually3 – a figure exacerbated by inadequate temperature control in warmer conditions.

Pressure on infrastructure and equipment longevity

Older refrigeration systems struggle to cope with sustained higher temperatures, leading to inefficiencies and an increased risk of failure. Indeed, refrigeration systems are designed to operate within specific ambient temperature ranges to ensure optimal performance and refrigerant capacity. When external temperatures exceed these maximum operating conditions, the cooling effect can be severely diminished or even cease to function entirely, leading to system failure and compromised cold rooms. The added stress on compressors and other components can significantly reduce their lifespan. Importantly, warmer ambient temperatures will directly impact the integrity and performance of warehouse buildings. Poorly insulated walls and roofs, especially large flat surfaces commonly found in warehouses, absorb and radiate more heat, making it even harder to maintain internal cold.

Problems such as thermal bridges (heat conduction through less insulated structural elements) become more pronounced, creating potential pathways for heat absorption. Damaged or ill-fitting cold storage doors can also become major culprits, allowing precious cold air to escape and warm air to enter, putting an extra strain on the cooling system. Therefore, a well-designed building is the first line of defence against external heat.

Challenges in transportation and last-mile delivery

The impact of warmer weather extends beyond warehouse walls. Transporting temperature-sensitive goods becomes more challenging. It is now more difficult for refrigerated trucks and containers to maintain consistent temperatures, especially during loading and unloading operations during which products are exposed to ambient heat. Complex last-mile deliveries, particularly in dense urban areas or remote regions, are also at higher risk of temperature variations as vehicles navigate traffic or extended routes.

Expert solutions: Adapting cold chain warehouses to a warming world

The good news is that the industry is not standing still. A proactive and strategic approach, leveraging both established best practices and cutting-edge technologies, is essential for mitigating the impact of warmer weather.

Enhancing insulation and building design

Keeping the heat outside is just as important as keeping the cold inside; this starts with the physical structure of a warehouse and its thermal envelope. It also involves a multi-pronged approach to insulation and building design:

- Underground storage

Keeping products cool underground could be considered, as the temperature of the earth is relatively more stable than the temperature of the air. Excavation costs and humidity control costs would need to be considered before choosing this solution.[3]&[4]

- High-performance insulation

Adding or upgrading advanced insulation materials with higher R-values (thermal resistance) in walls, roofs and floors is fundamental.

- Airtight construction

Minimising uncontrolled air leakage is important. This means paying attention to detail during construction, using air barriers and sealing all gaps and joints to prevent warm, moist air from entering, causing not only heat but also frost and condensation.

- Cool roof technologies

Applying highly reflective ‘cool roof’ coatings or materials for a roof’s surface can significantly reduce solar heat gain. These coatings effectively bounce sunlight away from the building rather than absorbing it, directly reducing the load on the cooling systems below.

- Airtight, fast-closing doors

In frequently accessed areas, installing high-speed, insulated doors minimises the exchange of air, preventing hot air infiltration and cold air loss. Polyvinyl chloride strip curtains can also be effectively used during loading operations.

- Optimising ventilation and passive design

While it may seem counterintuitive for cold spaces, intelligent ventilation systems, including high-volume, low-speed (HVLS) fans, can promote even air circulation and prevent hot air pockets in warehouses, improving overall thermal stability. Where feasible, incorporating passive design principles such as strategic building orientation to minimise sun exposure can further reduce heat gain.

Investing in energy-efficient and smart refrigeration systems

Upgrading to high-performance, energy-efficient refrigeration systems is paramount. Modern solutions offer precise temperature controls, lower operational costs and enhanced reliability. This includes technologies such as variable-speed compressors, which can adjust capacity to match the cooling load, and smart HVAC systems that utilise real-time data to optimise performance. These solutions are not merely about operational savings; they represent strategic investments with clear returns on investment through reduced energy expenditure and enhanced asset longevity. For example, research shows that retrofitting inefficient conventional refrigeration plants can lead to energy savings of up to 50 per cent.[5]

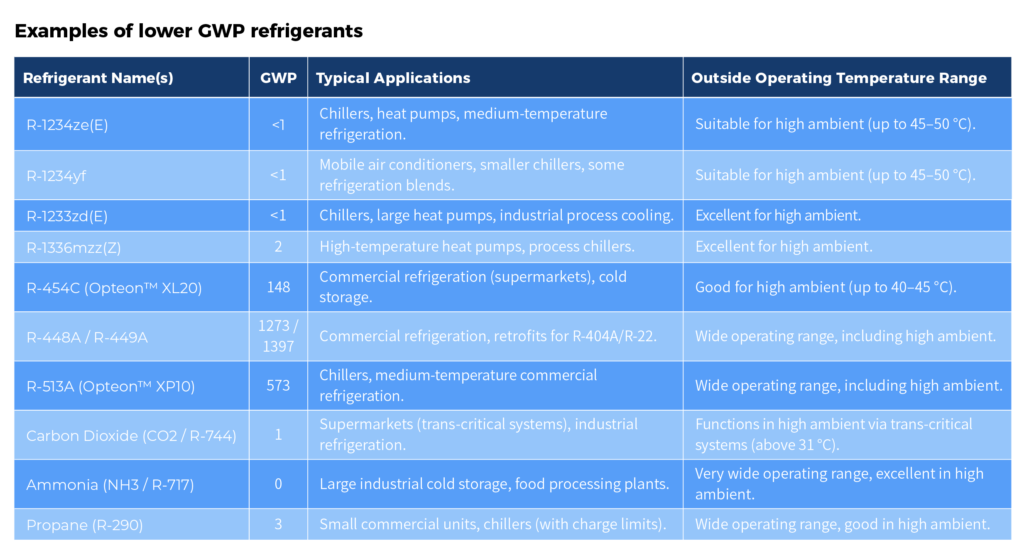

Technologies for a warming climate

Advances in refrigeration technology must be a key area of ongoing research and development for the cold chain. Innovations that focus on creating lower Global Warming Potential (GWP) alternatives that maintain efficiency and cooling capacity even during higher ambient temperatures can help to ensure system reliability in a warming climate.

Implementing advanced temperature monitoring and control

Real-time, continuous temperature monitoring is no longer a luxury but a necessity. Modern systems leverage internet-of-things sensors and artificial-intelligence-driven analytics to provide precise data across all zones of a warehouse. These systems can issue immediate warnings when there are any deviations from set thresholds, allowing proactive intervention before damage occurs. Integrating this data with warehouse management systems enables dynamic inventory control and optimised operations. Blockchain technology can further enhance transparency by creating an immutable temperature history record.

Prioritising preventative maintenance

A robust preventative maintenance programme is important to ensure refrigeration systems operate at peak performance, especially during periods of high demand. Regular cleaning and inspection of evaporators and condensers, checking refrigerant levels, testing sensors and electrical components, and scheduling routine maintenance before peak heat hits can prevent costly breakdowns and extend equipment life. For instance, actively managing defrost frequency and duration can reduce annual system energy use by approximately three per cent.[6]

Strategic planning and route optimisation

Effective logistics planning can mitigate heat exposure during transportation. This includes selecting the most efficient routes, avoiding areas of high temperatures, and timing shipments to bypass the hottest parts of the day or season. Advanced logistics software that integrates real-time weather data and traffic patterns can be invaluable in mapping optimal routes. Furthermore, pre-cooling fresh produce immediately after harvest can significantly slow spoilage, extending its shelf life.

The future of cold chain: Resilience and sustainability

The increasing frequency and intensity of warmer weather events underscore the urgent need for a more resilient and sustainable cold chain. Furthermore, to navigate the evolving landscape of regulatory compliance—particularly for pharmaceuticals and food safety, which necessitates advanced temperature control measures—the industry must embrace a forward-looking perspective. This includes exploring alternative energy sources such as solar photovoltaic systems to power cold storage facilities, adopting more environmentally friendly refrigerants, and funding research and development of new cooling technologies.

For true long-term sustainability, the focus must firmly extend to core building structures. Future cold chain warehouses will increasingly adopt green building certifications such as LEED, BREEAM or EDGE, demonstrating a commitment to environmental performance from the ground up. Integrating advanced building management systems with cooling controls will create truly smart buildings, optimising energy use based on external conditions and internal demands.

The impact of warmer weather on cold chain warehouses is undeniable and profound. It presents a complex web of challenges, from soaring energy costs and elevated operational disruptions to the rapid degradation of important infrastructure. However, by adopting advanced technologies, optimising operational practices and prioritising strategic planning, the cold chain industry can adapt and thrive in this changing climate.

Nathalie Ieong is senior expertise manager at TERAO. Thanh Tran is the company’s marketing manager.

TERAO is a French building

sustainability consultancy, with 30 years of pioneering experience. Since 2008,

TERAO has expanded its presence into Asia, with primary hubs in China, Vietnam,

Thailand, Singapore, Malaysia and the Middle East. The firm plans further

expansion into the rest of Southeast Asia, India, and other global locations. Specialising

in reducing the environmental impact of buildings, TERAO offers expertise for

both new constructions and existing assets across diverse sectors and building

types, including hospitality, manufacturing, retail, healthcare and more.

[1] Manufacturing: Introducing energy saving opportunities for business, Carbontrust, 2018, viewed 15th August 2024, <https://www.carbontrust.com/resources/manufacturing-sector-guide>

[2] Carrasco, J. C., Pascual-Guillamón, M, and Salas-Vicente, F, 2021, Improve the Energy Efficiency of the Cooling System by Slide Regulating the Capacity of Refrigerator Compressors, Applied Sciences, volume 11, issue 5, viewed 15th August 2025, MDPI host database, <https://www.mdpi.com/2076-3417/11/5/2019>

[3] The State of Food and Agriculture, Food and Agriculture Organization of the United Nations, 2019, viewed 15th August 2015, <https://openknowledge.fao.org/server/api/core/bitstreams/11f9288f-dc78-4171-8d02-92235b8d7dc7/content>

[4] For more information, see: Sustainable Cold Storage Logistics: How Underground Facilities Reduce Environmental Impact,Smart Warehousing, 28th October 2025, viewed 14th August 2025, <https://www.smartwarehousing.com/blog/sustainable-cold-storage-logistics-how-underground-facilities-reduce-environmental-impact>

[5] Karacan, M.A., Yilmaz, I.C., and Yilmaz, D., 2023, Key implications on food storage in cold chain by energy management perspectives, Frontiers in Sustainable Food Systems, vol. 7, viewed 15th August 2025, <https://www.frontiersin.org/journals/sustainable-food-systems/articles/10.3389/fsufs.2023.1250646/full>

[6] Fiscal Year 2020: Annual Performance Report, United States Environmental Protection Agency, January 2021, viewed 15th August 2025, <https://www.epa.gov/sites/default/files/2021-01/documents/epa-fy-2020-annual-performance-report.pdf>

Recent Comments