Opportunity for European companies?

2019 wasn’t easy for European companies in China. Business interruptions due to strict environmental enforcement, slowing growth and the trade war made many business leaders ponder on their China plans. More than the circular economy (CE), business ‘resilience’ and ‘transformation’ were high on the agenda. Yet, as Johnny Browaeys from GREENMENT tells us, CE seems to be the answer to both.

Recent studies by the Ellen MacArthur Foundation (EMF) and McKinsey Company show that the transition to a CE, enabled by the technology revolution, would allow both Europe and China to improve resource productivity and generate substantial economic benefits for EU industries. CE is a paradigm shift that revolutionises the way we design products, production and consumption patterns; in essence, the way we live.

Transformation GDP instead of growth GDP

Both Europe and China have understood this and share this vision for the future. This is illustrated by the European Commission’s recent Green Deal and by China’s ratification of “ecological civilisation” in its Constitution in 2018.

Europe’s approach is one of systematic adaptation of policies evolving from a long history of economic development, balancing many voices. China’s approach is one of piloting policies on-the-go (摸着石头过河 – crossing the river touching the stones) in a context of explosive economic growth, driven by one party/Party.

CE is not a new concept in China. To develop a CE became a national-level “mission” under the National Development and Reform Commission (NDRC) as early as 2004. The Circular Economy Promotion Law was approved in 2008. China: Promoting a Circular Economy is the final report of the programme developed by the World Bank in 2009 under the framework of the Italian Trust Fund for Environmental Protection in China.

Considering its status as manufacturing supply base for the world and leveraging international experience and best practices, China chose to drive leading manufacturing companies to develop green manufacturing and green supply chain management.“Green Manufacturing is considered an important milestone in China’s efforts to achieve an ecological civilization” according to Tao Mao, Director and Researcher at the Institute of Energy Resources and Environment.

The establishment of green factories became a strategic task, put forward in the Made in China 2025 initiative issued by the State Council in 2015. The Industrial Green Development Plan (2016–2020) was issued to establish a green manufacturing system by 2020.

In 2016, the first local green supply chain standards were issued in Tianjin: Green Supply Chain Requirements (DB12/T632-2016), Green Supply Chain Implementation Guideline (DB12/T662-2016) and Green Supply Chain Standardisation (DB12/T669-2016). These provided guidance for green procurement and for green supply chains in the fields of green buildings, houses, steel and other industries.

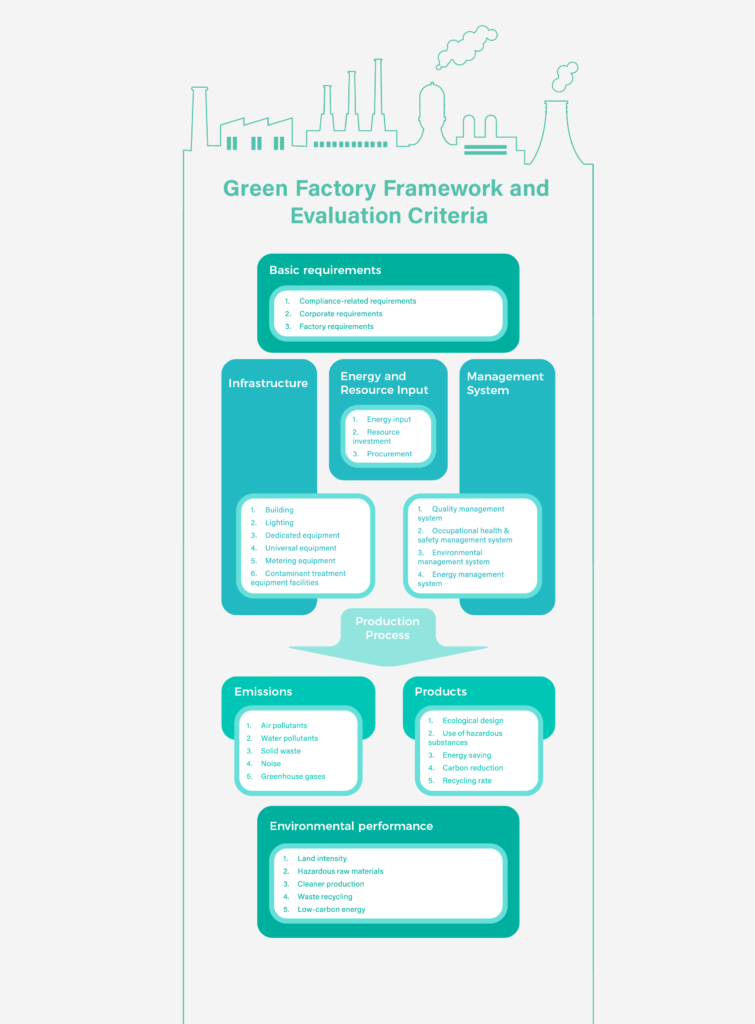

In December 2017, the first national-level standard, Green Supply Chain Management in Green Manufacturing (GB/T33635-2017), was rolled out. In 2018, green manufacturing criteria were established by General Rules for Green Factory Evaluation (GB/T 36132-2018), as illustrated below.

Specific requirements are put forward regarding major pollutants emissions from key industries, re-utilisation rates for industrial solid waste and energy consumption relative to industrial value added.

Incentives to participate

The List of National Green Supply Chain Management Demonstration Enterprises is growing rapidly, and local governments have started issuing various kinds of incentives. For example, Fujian province has given an award of Chinese yuan (CNY) 2 million to companies in this list. Other examples are found in Beijing, Tianjin, Shanghai, Jiangsu, Zhejiang, Anhui, Guangdong, and individual cities such as Hebi in Henan etc.

Via green supply chains and manufacturing to an ecological civilisation

The Green Manufacturing Association of China (GMAC), via the Green Manufacturing Alliance, invites companies to participate in raising the bar of Green Manufacturing in China, and facilitates the setup of professional committees to help develop green manufacturing industrial standards.

GMAC was established in 2017 to combine efforts by the government, industries, universities and research institutes to promote green transformation and upgrading of China’s manufacturing industry into a new engine for economic growth and new advantage in international competition.

From the above, it is clear that China is using a holistic and participative approach to create its ecological civilisation and that CE lies at its foundation. Green supply chains are required to minimise the consumption of energy and resources during production, minimise environmental impact, and maximise reutilisation. Enterprises are required to consider the ecological and environmental impacts from product design, procurement, production, sales, distribution, usage, recycling and treatments aimed at reuse. The aim is that green requirements placed on companies are not only passed on to upstream companies, but also extend downstream – eventually achieving recycling and reuse, resulting in economic and environmental benefits.

Enterprises that repeatedly refuse to change and that do not comply with these new requirements will be removed from the manufacturing supplier base, fading them out of existence.

Business risk management in China anno 2020

In this rapid-changing environment, compliance with regulations is not enough. Companies need to play ahead of the game, anticipate what is coming and how it will impact the business. A deep transformation of the Chinese industry is happening.

An example is the Jiangsu explosion last year which triggered factory upgrades, relocations, even closures. The incident in fact drives innovation across individual companies, industrial parks, and the industry as a whole. Other examples include cases where poor ambient air or surface water quality is triggering local governments to restrict company operations and/or insist on factory facility upgrades. In parallel, local, provincial and national governments are reviewing urban, industrial and ecological planning and subsequently plan relocations, closures of factories, and, in some cases, even entire industrial parks.

This means that external, dynamic, events are impacting companies through “real-time policy adaptations” that are raising the bar for the industry, balancing society’s need for safe and clean environments and employment. Recently, China started digitising information and government information channels, making this information available real-time via numerous online sources. Leading companies are moving to digital “big data” environmental risk management tracking abovementioned dynamic events real-time to anticipate and mitigate impacts on the business.

Environmental credit scoring in 2020 and beyond

China’s Corporate Social Credit System, which is set to be rolled out fully by the end of 2020, but is already running as a pilot, uses a ‘digital hand’ to monitor, score and individually drive the environmental performances of companies in China via a “one company, one policy” approach.

Some of the mechanisms under consideration in upcoming regulations are disclosure of environmental ratings, differentiated supervision based on credit levels, various market and industry ban mechanisms. Examples include the issuance of production safety licenses, restrictions on new projects and land supply, government-based procurement, restrictions on financing/bonds, restrictions on stock transfers, and implications with respect to environment liability, among others.

Getting certified as a Green Manufacturing Company for example helps to increase your rating and get exempted from inspections or production restrictions during poor air quality alerts. Under these conditions, environmental protection ‘dividends’ will gradually increase. Green manufacturing companies building green supply chains will not only be more resilient, but their market share will increase accordingly, led by leading companies, followed by their followers.

Europe and China

Policy discourse and recent legislation (2015–2017) in both regions are converging to challenge the traditional model of linear economy (take, make, dispose). The Memorandum of Understanding (MOU) on Circular Economy Cooperation signed at the 20th EU-China Summit (July 2018) is an important milestone. The transition to CE in the worlds’ two largest economies would accelerate a global “system shift” towards a low carbon regenerative economy, said Arvea Marieni, a CE expert at the international conference ‘EU-China 2020 Strategic Agenda for Cooperation’ of the College of Europe.

From a cross-continent Europe-China perspective, various instruments for cooperation and convergence exist such as Best Available Techniques Reference Documents (BREFs), innovation partnerships, joint technology initiatives etc.

Understanding and bridging the cultural difference with China

People in Europe often ask me how people and businesses in China deal with the impacts of the sometimes incredibly fast transformation. I would like to suggest you read and feel “乘风破浪会有时直挂云帆济沧海” by one of China’s most famous poets Li Bai from the Tang Dynasty. This poem often successfully has been used by Chinese leaders to aspire its population to accept hardship, inspire accountability, to build confidence and to drive participation in overcoming difficulties that lie ahead. I am often amazed how such messages in China can make “1,4 billion noses change direction almost overnight”. I attribute it to the fact that Chinese people associate their country with a large family (国家 guo jia) and that in families (家庭 jia ting) Chinese people have a sense of collective responsibility that goes beyond the individual, as reflected in Confucianism.

Katsushika Hokusai using western painting technique to picture the story of Li Bai’s poem, nicely illustrates the message in this poem, and also proves we can inspire each other across borders.

Some thoughts to take home, how to prepare for what’s coming?

Global natural resource exploitation is accelerating in the face of resource decline. Population and income growth drive up demand for energy, materials and food. According to the International Resource Panel Report, global material resource usage, which was nearing 90 billion tonnes in 2017, is forecast to double between 2015 and 2050.

Humankind is operating beyond the planetary boundaries that allow life on earth. The way CE rolls out in China and Europe is of such a scale that it has the potential to transform the world. Let’s remind ourselves we cannot afford to be distracted by ideological differences. Mutual trust, respect, acceptance and a genuine desire to make it work are key for a sustainable relationship. With the philosophy of only having one ‘Circular Earth’ in mind, let’s focus on getting things done. Or we might as well all call Elon Musk and sign up for a ticket to Mars.

2020 may be the time for you to re-strategize around CE and New Technologies. As a European company, how can you leverage your link with China? How to better work with your Chinese teams and Chinese business partners? How to make your business more resilient? How to gain market share? How to outperform your competition?

How to “Ride the wave until you become the wave”?

Contributor

Johnny Browaeys is the national vice chair of the European’s Chamber’s Environmental Working Group, and director of GREENMENT Environment

GREENMENT was formed in 2012 from the North Asia Division of CH2M, part of the world biggest environmental consulting and engineering group. (CH2M was merged into Jacobs in 2017). GREENMENT has its representative offices in Shanghai, Beijing, Guangzhou, Brussels-Belgium and Silicon Valley.

GREENMENT has developed the DERA (Dynamic Environmental Risk Assessment) system which taps into China’s new ‘big’ data channels that allow companies to prioritise, anticipate and mitigate business risks.

GREENMENT is authorised to perform Green Factory Evaluations and holds professional licences for Soil and Groundwater Remediation, Environmental Impact Assessment and Permitting, and Occupational Health & Safety.

Recent Comments